Rust Preventive Oil Market size was valued at US$ 13.30 Bn. in 2022, and the total Rust Preventive Oil revenue is expected to grow at 4.9% from 2023 to 2029, reaching nearly US$ 18.59 Bn.Rust Preventive Oil Market Overview:

Rust preventive oils or Corrosion Inhibitors are used for the protection of metal surfaces from atmospheric corrosion. Rust forms when iron comes into contact with water or oxygen. This can cause equipment failure and damage to machinery. Application of rust preventive oils to the metal parts helps the user to prevent the corrosive attack and saves a significant amount of money for the business. Rust inhibitor sprays and solvents prevent corrosion by producing a thin protective coating on the metal's surface. This prevents electrolytes such as water and salts from getting into touch with the surface delaying the oxidation process. This barrier film protects the surface from oxygen, water, and other chemically active molecules in the environment. Rust preventative oils are widely utilized in a variety of sectors, including automotive, coatings, food and drinks, and construction.To know about the Research Methodology:-Request Free Sample Report In this report, the Rust Preventive Oil market's growth reasons, as well as the market's many segments (Type, Application, and Region), are discussed. Data has been given by market players, regions, and specific requirements. This market report includes a comprehensive overview of all the significant improvements that are presently prevailing in all market segments. Key data analysis is presented in the form of statistics, infographics, and presentations. The study discusses the Rust Preventive Oil market's Drivers, Restraints, Opportunities, and Challenges. The report helps to assess the market growth drivers and determines how to use these drivers as a tool. The report also helps to rectify and resolve issues related to the global Rust Preventive Oil market situation.

Dynamics:

The increased use of rust preventative oils in sectors such as automotive, construction, food and beverages, and paints is a significant driving force in the market's growth. The rust preventive oil has several advantages, such as non-staining capabilities, compatibility with lubricating oils, ease of application by swab, spray, or brush, wide-coverage, and ease of removal by solvent, which are eventually driving the market growth. Rising use of rust preventive oils in factory machines, gardening tools, and bicycles to protect their parts from corrosion. Anti-rust oil is becoming increasingly popular in the market because it prevents the formation of rusts, as well as corrosion and machine wear and tear. The need for industrial oils is growing as they assist many industries in keeping their systems up to date at cost-effective pricing. Anti-Rust Oil Spray may also help users in removing all symptoms of corrosion and keeping their objects in good condition. Rust Preventive Oil used in the automobile industry: In the automobile sector, rust preventative oils are widely utilized to improve the efficiency of cooling systems, brake systems, and other components. These oils serve as lubricants for metal components while also preserving them from corrosion. Vehicles' metal bodies and engines are extremely prone to corrosion. Rust prevention oils are used to keep an automobile's body, engine, and brakes from rusting by protecting these components from direct contact with moisture and oxygen in the environment. Furthermore, metal parts of automobiles are exposed to moisture and oxygen-rich air as they travel from inventories to assembly lines. As a result, rust protection oil must be used at every stage of automobile manufacturing. Thus, the market for Rust Preventive Oil is increased in recent years. Use in Construction Sector: Rust preventative oils are extremely useful in the construction sector for preventing corrosion from damaging the valuable metals used in infrastructure. By covering the metal pieces of construction equipment and machinery, these lubricants also protect them. This protective layer of coating functions as a lubricant allowing internal components to move smoothly. The oxidation and reduction processes are greatly increased during the monsoon, with rainwater acting as a catalyst. As a result, paints are blended with rust-preventive oils and applied to metallic structures. Prevent corrosion on equipment used in an acidic environment: Acidic chemicals are particularly harmful to metals and cause significant quality deterioration through increasing corrosion. Even if the metal is not directly exposed to acids, it may be absorbed through the atmosphere, groundwater, or soil. Equipment exposed to an acidic environment is coated with rust preventive oil, which acts as a barrier to prevent the acid from reaching its surface. Growing industrialization in developing economies: Infrastructural development in nations such as China, India, Brazil, and South Korea is expected to boost industrial activity and contribute to the growth of their economies. In the next five years, infrastructure growth connected to energy demand, clean water need, fuel demand, transportation demand, and construction demand is likely to drive the corrosion inhibitors market. As a result, growing economies are increasing their usage of industrial water. This allows manufacturers to provide a comprehensive range of Rust Preventive Oil to various applications in order to protect them against corrosion. Rust Preventive Oil market Restraint: The primary factors hampering the growth of the corrosion inhibitor market are stringent environmental regulations. The increased concern about the impact of chemicals on the environment and human health has resulted in stricter regulatory limits for corrosion inhibitor Rust, Preventive Oil manufacturers. This encourages producers to choose non-toxic alternatives. The ability of non-toxic corrosion Rust Preventive Oil formulations to work under harsh circumstances makes it difficult for producers to supply an alternative to standard formulations. Rust Preventive Oil is Messy to use, and the coatings can attract dirt and spills. Sometimes Oil also makes it difficult to grasp an object and can cause parts to slip or become unbalanced. It can also be filthy and difficult to work with. Furthermore, the Oils and solvents may require careful handling since they are dangerous and combustible. It might be costly to dispose of old or used oil.Rust Preventive Oil Market Segment Analysis:

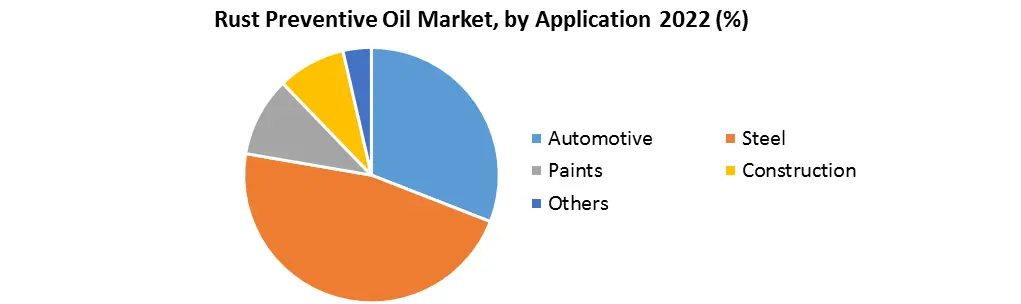

By Type, a water-soluble RP segment is applied to the Finned Tube material of a heat exchanger used in a heat recovery steam generator of a cogeneration power plant or a boiler. According to rust preventative oil makers, water-based solutions are environmentally friendly. The current invention's rust preventative oil provides heat loss, rust prevention, and environmental friendliness. The water-soluble anti-corrosive oil has nearly no volatile organic solvents (VOCs). It is painted either alone or by combining and diluting with paint and diluent. By Application, the Paint segment is expected to grow at a rapid rate owing to the increase in construction activities. Rust preventive oils are commonly added to paints and used as a coating on the bridge to maintain their lifetime despite the weather conditions. To avoid corrosion, the metal used in construction is coated with rust preventive oil before it is shipped.

Rust Preventive Oil Market Regional Insights:

APAC is the rust preventive market's fastest-growing region. Factors such as rising population, increasing industrial growth, and growing environmental awareness are driving demand for water treatment chemicals in the area and have a direct impact on the rust preventive oil market. The increase in the number of end-use industries in the area is also leading to inventions and advances, fueling the growth of the Rust Preventive Oil Market. In Europe, the Rust Preventive Oil market is expected to grow owing to the massive consumption of water for industrial sectors such as sugar and ethanol and petrochemical industries. Water treatment concerns in Europe play a critical part in corrosion control activities, as well as preserving the operational integrity of heat transfer equipment and reducing the negative impact on process unit energy efficiency. The objective of the report is to present a comprehensive analysis of the Rust Preventive Oil market to the stakeholders in the industry. The past and current status of the industry with the forecasted market size and trends are presented in the report with the analysis of complicated data in simple language. The report covers all the aspects of the industry with a dedicated study of key players that include market leaders, followers, and new entrants. PORTER, PESTEL analysis with the potential impact of micro-economic factors of the market have been presented in the report. External as well as internal factors that are supposed to affect the business positively or negatively have been analyzed, which will give a clear futuristic view of the industry to the decision-makers. The report also helps in understanding the Rust Preventive Oil market dynamics, and structure by analyzing the market segments and projecting the Rust Preventive Oil market size. Clear representation of competitive analysis of key players by product, price, financial position, product portfolio, growth strategies, and regional presence in the Rust Preventive Oil market make the report investor’s guide.Rust Preventive Oil Market Scope: Inquire before buying

Global Rust Preventive Oil Market Report Coverage Details Base Year: 2022 Forecast Period: 2023-2029 Historical Data: 2018 to 2022 Market Size in 2022: US $ 13.30 Bn. Forecast Period 2023 to 2029 CAGR: 4.9 % Market Size in 2029: US $ 18.59 Bn Segments Covered: by Type Dry Non-dry Water Soluble by Application Automotive Steel Paints Construction Others by Region

North America (United States, Canada and Mexico) Europe (UK, France, Germany, Italy, Spain, Sweden, Austria and Rest of Europe) Asia Pacific (China, South Korea, Japan, India, Australia, Indonesia, Malaysia, Vietnam, Taiwan, Bangladesh, Pakistan and Rest of APAC) Middle East and Africa (South Africa, GCC, Egypt, Nigeria and Rest of ME&A) South America (Brazil, Argentina Rest of South America)Rust Preventive Oil Market Key Players

1. ExxonMobil 2. Chemtool Incorporated 3. DoALL Sawing Products 4. ITW Chemin 5. Rust-X 6. Houghton International Inc 7. Rust Check 8. Condat Group 9. Ashburn 10.Eni Oil Products 11.Hindustan Petroleum 12.Suprabha 13.Eastern Petroleum 14.Zerust 15.Long Lub-Tek Corporation 16.Mount Shivalik Chemicals 17.Witmans Advanced Fluids 18.Croda 19.Nippon Grease 20.HP Lubricants FAQs: 1. Which is the potential market for Rust Preventive Oil in terms of the region? Ans. In the APAC region, rising population, increasing industrial growth, and growing environmental awareness are driving demand for water treatment chemicals in the area and have a direct impact on the rust preventive oil market. 2. What are the opportunities for new market entrants? Ans. The growing economies are increasing their usage of industrial water. This provides an opportunity for manufacturers to provide a diverse variety of corrosion inhibitors to varied applications in order to protect them against corrosion. 3. What is expected to drive the growth of the Rust Preventive Oil market in the forecast period? Ans. A major driver in the Rust Preventive Oil market is Growing industrialization in developing economies. 4. What is the projected market size & growth rate of the Rust Preventive Oil Market? Ans. Rust Preventive Oil Market size was valued at US$ 13.30 Bn. in 2022, and the total Rust Preventive Oil revenue is expected to grow at 4.9% from 2023 to 2029, reaching nearly US$ 18.59 Bn. 5. What segments are covered in the Rust Preventive Oil Market report? Ans. The segments covered are Type, Application, and Region.

1. Global Rust Preventive Oil Market: Research Methodology 2. Global Rust Preventive Oil Market: Executive Summary 2.1 Market Overview and Definitions 2.1.1. Introduction to Global Rust Preventive Oil Market 2.2. Summary 2.2.1. Key Findings 2.2.2. Recommendations for Investors 2.2.3. Recommendations for Market Leaders 2.2.4. Recommendations for New Market Entry 3. Global Rust Preventive Oil Market: Competitive Analysis 3.1 MMR Competition Matrix 3.1.1. Market Structure by region 3.1.2. Competitive Benchmarking of Key Players 3.2 Consolidation in the Market 3.2.1 M&A by region 3.3 Key Developments by Companies 3.4 Market Drivers 3.5 Market Restraints 3.6 Market Opportunities 3.7 Market Challenges 3.8 Market Dynamics 3.9 PORTERS Five Forces Analysis 3.10 PESTLE 3.11 Regulatory Landscape by region • North America • Europe • Asia Pacific • The Middle East and Africa • South America 3.12 COVID-19 Impact 4. Global Rust Preventive Oil Market Segmentation 4.1. Global Rust Preventive Oil Market, by Type (2022-2029) • Dry • Non-dry • Water Soluble 4.2. Global Rust Preventive Oil Market, by Application (2022-2029) • Automotive • Steel • Paints • Construction • Others 5. North America Rust Preventive Oil Market(2022-2029) 5.1 North American Rust Preventive Oil Market, By Type (2022-2029) • Dry • Non-dry • Water Soluble 5.2 North America Rust Preventive Oil Market, By Application (2022-2029) • Automotive • Steel • Paints • Construction • Others 5.3 North America Rust Preventive Oil Market, by Country (2022-2029) • United States • Canada • Mexico 6. European Rust Preventive Oil Market (2022-2029) 6.1. European Rust Preventive Oil Market, By Type (2022-2029) 6.2. European Rust Preventive Oil Market, By Application (2022-2029) 6.3 European Rust Preventive Oil Market, by Country (2022-2029) • UK • France • Germany • Italy • Spain • Sweden • Austria • Rest Of Europe 7. Asia Pacific Rust Preventive Oil Market (2022-2029) 7.1. Asia Pacific Rust Preventive Oil Market, By Type (2022-2029) 7.2. Asia Pacific Rust Preventive Oil Market, By Application (2022-2029) 7.3. Asia Pacific Rust Preventive Oil Market, by Country (2022-2029) • China • India • Japan • South Korea • Australia • ASEAN • Rest Of APAC 8. Middle East and Africa Rust Preventive Oil Market (2022-2029) 8.1. Middle East and Africa Rust Preventive Oil Market, By Type (2022-2029) 8.2. Middle East and Africa Rust Preventive Oil Market, By Application (2022-2029) 8.3. Middle East and Africa Rust Preventive Oil Market, by Country (2022-2029) • South Africa • GCC • Egypt • Nigeria • Rest Of ME&A 9. South America Rust Preventive Oil Market (2022-2029) 9.1. South America Rust Preventive Oil Market, By Type (2022-2029) 9.2. South America Rust Preventive Oil Market, By Application (2022-2029) 9.3 South America Rust Preventive Oil Market, by Country (2022-2029) • Brazil • Argentina • Rest Of South America 10. Company Profile: Key players 10.1 ExxonMobil 10.1.1. Company Overview 10.1.2. Financial Overview 10.1.3. Global Presence 10.1.4. Capacity Portfolio 10.1.5. Business Strategy 10.1.6. Recent Developments 10.2 Chemtool Incorporated 10.3 DoALL Sawing Products 10.4 ITW Chemin 10.5 Rust-X 10.6 Houghton International Inc 10.7 Rust Check 10.8 Condat Group 10.9 Ashburn 10.10 Eni Oil Products 10.11 Hindustan Petroleum 10.12 Suprabha 10.13 Eastern Petroleum 10.14 Zerust 10.15 Long Lub-Tek Corporation 10.16 Mount Shivalik Chemicals 10.17 Witmans Advanced Fluids 10.18 Croda 10.19 Nippon Grease 10.20 HP Lubricants