3D printing technology market is one of the leading and fastest flourishing markets in the world. 2012 was a turning point in 3D printing technology, universally,” consultancy Wohlers Associates president Terry Wohlers tells Engineering News Online. The technology really grew attention, investment, and traction, in comparison to what had been the case previously.” 3D printing is booming by nearly every metric—unit sales, total manufacturing revenue, adoption levels—the technology has expanded rapidly in recent years. As per the market analysis, the 3D printing market is evaluated at about US$ 9.9 billion and is anticipated to reach US$ 34.8 billion by 2024. The numbers are remarkable and act as a big inspiration for investments in this sector. Emerging applications in several industries, potential to improve manufacturing processes and enhance supply chain management this creates a unique opportunity for 3D printing technology market.

According to global market analysis, the United States is the global leader in 3D printing technology market, this country has early entry into additive manufacturing and its historic leadership in traditional manufacturing. However, A.T. Kearney’s 2017 3D Printing Index discloses that the United States is a threat of falling behind as countries such as Germany, Korea, Italy, and the United Kingdom picked up the pace and new player’s like the United Arab Emirates and Saudi Arabia enter the field. However, Italy is encouraging companies to adopt 3D printing, mostly in jewelry and metal products, as a way to progress manufacturing competitiveness. The china plans to install 3D printers in all 400,000 elementary schools within the next two years because by using several existing 3D printing technologies country is sheathing in both 3D education and general secondary education and digital skills.

Currently, in the global 3D printing technology market, there are much 3D printing technologies are available such as polymer-based 3D printing, Metal based, injection molding, CNC machining, fused deposition molding, and selective laser sintering and many more. But the $14 trillion worldwide market remains dominated by more conventional methods, especially CNC machining and injection molding. 3D-printed materials are still largely binary, it’s supportive to consider the industry’s growth relative to these traditional techniques in dual terms. Polymers are the most commonly used 3D-printed materials today. Polymer-based additive manufacturing naturally matches injection molding as a production technique, since plastics include the vast majority of the market for mold-produced products. Also as systems expand, it is projected that a plastic 3D printing is also rising more rapidly relative to its size.

The increasing use of the polymer-based 3D printing technology instead of injection modeling technique for 3D printing is the major key trend of 3D printing technology market. Trades of industrial-class polymer printers jumped significantly in the market it is a clear reflection of 3D printing’s increasing relevance in production at scale. Furthermore, unit sales across all classes have seen incredible growth over the past four years, jumping from just over 100,000 units dispatched in 2014 to almost 500,000 last year. In economic terms, the growth has been even more substantial. After a period of immobility in the early 2010s, the market of polymer-based additive manufacturing sector raised at a compound annual growth rate of 29 percent over the same period to reach $6 billion in 2017.

Metal 3D printing is gripping the global 3D printing technology market versus CNC machining. Metal 3D printing is easy to compare to CNC machining because it parallels CNC machining as a production technique. Hence metals dominate the machine-manufactured landscape. In the past year alone, shipments of metal 3D printing systems enlarged by almost 80 percent year-over-year. That increase brought the CAGR of metal printing units to over 50 percent since 2014. The market is becoming crowded a difficult thing for some separable firms, sure, but a positive development for raising the invention and competition that will boost the technology forward.

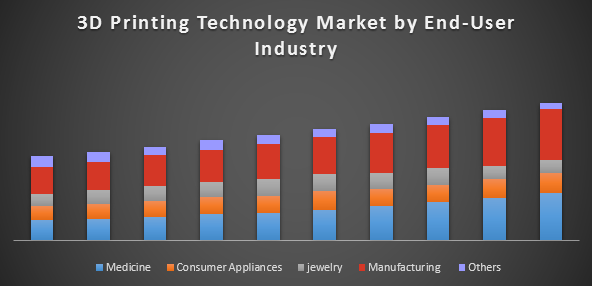

The 3D printing has been found to be useful in sectors such as construction, medicine, manufacturing, healthcare, consumer and appliances, automotive, aerospace, industrial design, jewelry, footwear, architecture, engineering and construction, automotive, aerospace, dental and medical or medicine industries, education, geographic information systems, civil engineering, and many others. The applications of 3D printing are ever growing and it’s proving to be a very stimulating technology to look out for. Therefore one of the major factors which are fuelling the growth of 3D printing technology is its ever-growing applications in various sectors.

Increased global competition among the different countries to achieve leading position in the global market, increasing use of 3D printing in manufacturing industries, developments in lasers, inkjet, printing heads, photopolymers and other technologies making their adoption for 3D printing cheaper and more likely, raising use of 3D printing technology in medical sector, growing adaption of 3D printers owing to its advantages over other printers, increased efficiency in the production, evolution of different 3D printing technologies and the decentralization and democratization of many things like payments, retail, online auctions and so on are mainly drives the growth of the global 3D printing technology market.

The manufacturing sector is contributing to the larger share of 3D printing technology market between others sector because this technology skipped the prototype stage in the manufacturing sector and go straight to the end product. The 3D printers are mostly used in the automotive and aerospace industry for the printing of the airplane and vehicle parts. The printing of parts is being done in a fast and efficient manner by using 3D technology thus contributing immensely to the value chain is expected to support the growth of 3D technology in the manufacturing sector. So that automotive and aerospace manufacturing industries are projected to hold the largest market share during the forecast period.

Also, the medical sector has tremendous usage of the 3D printing in the different field of the medical sector such as the field of bionics, hearing aids, bioprinters, prosthetics, digital dentistry, and artificial organs are expected to produce various growth opportunities for 3D printing technology. Hearing aids have been made using 3D printing technology which drives the 3D printing technology market in the medical sector. In the medical sector, 3D printed organs and skin grafting is expected to grow the 3D printing technology in the upcoming years. Also, 3D printing technology is expected to make human organs for the necessity of peoples one day. Advantages of the 3D printer are endless therefore it is the most preferable technology.

Conferring to research by global market insights, the 3D printing material & equipment market in the Asia Pacific is anticipated to witness high growth in the upcoming years, owing to the considerable growth of manufacturing in sectors such as automotive and aerospace sectors. The rapid technological advancements in the 3D printing technology are expected to create growth opportunities for 3D printing technology in the future. Further, the opportunities for 3D printing technology of the India market are evolving along with the need and changes in the lifestyle of the Indian consumer. Companies are realizing the need for quicker and more efficient alternatives. This upwelling in 3D printing will make a whole new category of new jobs and investment opportunities for 3D printing technology. Also, Wipro 3D is previously witnessing good traction with clients in Space, Aerospace, Defense and Automobile. Market researchers believe this will accelerate the faster opportunities for 3D printing technology in the future.

In the future the 3D technology is expected to deploy in every home if they want to make any toy or anything then they will purchase the 3D file instead of the product. The 3D printing technology has potential to improve manufacturing processes, enhance supply chain management and also this technology is projected to expand in various industries are projected to ample the several opportunities for 3D printing technology during the forecast period. 3D printing, or additive manufacturing, has the potential to democratize the manufacture of goods, from food to medical supplies, to great coral ranges. In the future, 3D printing machines could mark their way into homes, businesses, disaster sites, and even outer space.