Micro Injection Molded Plastic Market size was valued at USD 1.1 Bn. in 2022 and the total Micro Injection Molded Plastic revenue is expected to grow by 11.9 % from 2023 to 2029, reaching nearly USD 2.2 Bn.Micro Injection Molded Plastic Market Overview:

Micro Injection Molded Plastic involves the precise production of intricate plastic parts with dimensions ranging from sub-millimeter to a few millimeters, utilizing specialized injection molding techniques. The micro injection molded plastic market is experiencing strong growth due to the increasing demand for small and intricate plastic components across various industries. Key drivers of this market include advancements in micro-injection molding technology, the need for miniaturization, and the rising demand for high-performance plastic components. The automotive industry is a significant consumer of micro injection molded plastic parts, employing them in connectors, sensors, switches, and housing components. Similarly, the medical devices sector relies on micro injection molded plastic parts for surgical instruments, drug delivery systems, and microfluidic devices. In the electronics industry, these parts find applications in connectors, switches, and small housing components. Micro Injection Molded Plastic Market growth is propelled by factors such as the growing demand for lightweight and compact products, advancements in material science, and the pursuit of high precision and quality. Additionally, the adoption of micro injection molded plastic parts is expanding into emerging industries like telecommunications, aerospace, and consumer goods. However, challenges exist within the market, including high costs associated with tooling and equipment, complex mold design requirements, and the need for skilled operators. Furthermore, environmental concerns and the demand for sustainable and bioresorbable materials are shaping the market landscape.To know about the Research Methodology :- Request Free Sample Report

Micro Injection Molded Plastic Market Dynamics

Micro Injection Molded Plastic Market Drivers Growing Demand for Miniaturized and Complex Plastic Components Drives the Micro Injection Molded Plastic Market The micro injection molded plastic market is experiencing robust growth due to the escalating demand for miniaturized and complex plastic components across various industries. Several causes are driving this spike in demand, including technological improvements, the pursuit of high precision and quality, and the growing tendency of miniaturization in product design. Automotive, medical devices, electronics, telecommunications, and consumer goods industries are actively seeking smaller and finely engineered plastic parts to meet increasing customer wants and market trends. For instance, the automotive sector requires micro injection molded plastic parts for connectors, sensors, switches, and housing components in modern vehicles. Similarly, the medical devices industry relies on micro injection molded plastic parts for surgical instruments, drug delivery systems, and microfluidic devices. Moreover, the industry-wide emphasis on miniaturization in product design, driven by the need for lightweight and compact solutions, is a significant driver for the micro injection molded plastic market. Miniaturized components offer advantages such as optimized space utilization, improved performance, and enhanced functionality across various applications. Additionally, the growing demand for high-performance plastic components contributes to the market's expansion. These components necessitate the use of precise engineering-grade materials capable of withstanding demanding operating conditions while exhibiting excellent mechanical properties, as well as superior electrical and thermal performance. Micro injection molding facilitates the production of such high-performance plastic parts with intricate designs and tight tolerances. Moreover, the micro injection molded plastic market thrives on the escalating demand for miniaturized and complex plastic components in industries like automotive, medical devices, electronics, telecommunications, and consumer goods. This demand is fueled by technological advancements, the need for high precision and quality, and the trend toward miniaturization in product design. Market players like EVCO Plastics , and Stack Plastics are actively engaged in developing innovative solutions and expanding their capabilities to meet the rising demand for these specialized plastic components. Micro Injection Molded Plastic Market Restraints Cost and Complexity of Mold Design and Skilled Operator Requirement Pose Challenges The growth of the micro injection molded plastic market is accompanied by certain restraints that impede its full potential. One of the primary restraints is the cost and complexity involved in mold design, as well as the need for skilled operators. Designing and developing molds for micro injection molding can be a meticulous and time-consuming process. The intricate dimensions and complex geometries of the desired plastic components necessitate precise mold design and manufacturing. This involves specialized expertise, extensive testing, and iterative adjustments to ensure that the molds meet the required tolerances and specifications. The cost of mold design and production can be significant, particularly for custom and intricate designs, which may limit market accessibility for certain manufacturers. Moreover, operating micro injection molding machines and processes requires skilled operators who possess in-depth knowledge of the technology and its intricacies. These operators must be proficient in mold setup, machine programming, material handling, and troubleshooting. Acquiring and retaining such skilled personnel can be challenging for manufacturers, particularly in regions where there is a shortage of qualified professionals. The requirement for skilled operators adds to overall production costs and may restrict the scalability of micro injection molded plastic production. Additionally, there is an increasing emphasis on addressing sustainability and environmental considerations in the market. While micro injection molded plastic parts offer numerous functional and performance advantages, the environmental impact of conventional plastics and the absence of bioresorbable or sustainable materials in micro injection molding pose a restraint in an era of heightened environmental consciousness. To overcome these restraints, the micro injection molded plastic market is witnessing ongoing efforts to simplify mold design processes, reduce costs, and develop automated systems to streamline operations. Micro Injection Molded Plastic Market Opportunity Growing Adoption of Micro Injection Molded Plastic in Emerging Industries Presents Significant Growth Potential The micro injection molded plastic market is witnessing a significant opportunity fueled by the rising adoption of micro injection molded plastic in emerging industries. This trend paves the way for market expansion and showcases the potential for sustained growth in the foreseeable future. Industries such as telecommunications, aerospace, and consumer goods are increasingly recognizing the advantages offered by micro injection molded plastic components. These industries have a growing need for small and intricate plastic parts to meet evolving demands, achieve higher levels of performance, and enhance miniaturization and functionality. The utilization of micro injection molded plastic parts enables these industries to attain their objectives and cater to the specific requirements of their products. The telecommunications sector, for instance, is driven by the demand for compact and lightweight devices, creating a need for miniaturized plastic components. Micro injection molded plastic parts find application in connectors, switches, and housing components of telecommunication devices, contributing to their overall performance and functionality. The aerospace industry benefits from adopting micro injection molded plastic parts across various applications. These parts are utilized in connectors, sensor housings, brackets, and other components that require precision, reliability, and lightweight characteristics. Given the aerospace industry's stringent quality and performance requirements, micro injection molded plastic presents an attractive option for manufacturers. The consumer goods industry also leverages micro injection molded plastic to enhance product design and functionality. From small electronic devices to personal care products and household appliances, micro injection molded plastic components offer improved aesthetics, durability, and intricate designs that enhance the overall consumer experience. The increasing adoption of micro injection molded plastic in these emerging industries presents significant growth opportunities for market players. North America, Europe, Asia Pacific, and South America are experiencing notable market activity, driven by the growing demand for micro injection molded plastic across various industries. These regions offer lucrative prospects for market players to establish a robust presence, collaborate with key industry stakeholders, and tap into the expanding demand for micro injection molded plastic components. Moreover, the increasing adoption of micro injection molded plastic in emerging industries such as telecommunications, aerospace, and consumer goods presents an enticing market opportunity. Manufacturers capable of effectively addressing the specific requirements of these industries and providing high-quality plastic components have the potential to capitalize on this opportunity and drive substantial growth in the micro injection molded plastic market.Micro Injection Molded Plastic Market Segment Analysis:

Based on Material Type, the micro injection molded plastic market is dominated by the Polycarbonate segment in the year 2022, and is expected to continue its dominance during the forecast period. Its high impact resistance and optical clarity make it suitable for ensuring safety and providing effective lighting solutions. Polycarbonate is also utilized in interior components like instrument clusters, buttons, and trim parts, where its dimensional stability and aesthetic appeal are highly valued. In the electronics industry, Polycarbonate finds application in micro injection molded plastic parts for electrical connectors, switch housings, and display components. Its excellent electrical insulation properties, heat resistance, and dimensional stability contribute to reliable and durable electronic devices. The medical devices sector also relies on Polycarbonate for micro injection molded plastic parts used in medical equipment and devices. It is often chosen for its biocompatibility, transparency, and ability to withstand sterilization processes. Polycarbonate components are used in surgical instruments, drug delivery systems, fluid handling systems, and diagnostic devices. Furthermore, Polycarbonate is employed in the production of consumer goods such as eyewear, protective gear, and household appliances. Its impact resistance, lightweight nature, and aesthetic appeal make it a suitable material for these applications.Based on the Process, the micro injection molded plastic market is dominated by the Hot runner injection molding segment in the year 2022 and is expected to continue its dominance during the forecast period. Hot runner injection molding is a highly popular process widely utilized for producing microplastic components due to its numerous advantages. In hot runner injection molding, a heated manifold system is employed to deliver molten plastic directly into the mold cavity, eliminating the need for a conventional cold runner system. The hot runner system comprises heated nozzles and channels that maintain the plastic material in a molten state, ensuring efficient and precise injection. One of the primary benefits of hot runner injection molding is the reduction in material waste. Unlike cold runner injection molding, which typically discards the unused plastic in the runner system, hot runner molding eliminates the need for runners, leading to decreased material waste and improved cost-effectiveness. Furthermore, hot runner injection molding facilitates faster cycle times and enhanced production efficiency. By maintaining the molten plastic at an optimal temperature, the cooling time required between injection cycles is minimized. This enables accelerated production rates and shorter lead times, making hot runner injection molding ideal for the high-volume production of microplastic components. Additionally, hot runner injection molding contributes to improved part quality and consistency. The precise control over the temperature and flow of the molten plastic ensures uniform filling of the mold cavities, thereby minimizing the risk of defects such as warping, sink marks, or uneven filling. The elimination of the cold runner system also reduces the chances of contamination or degradation of the plastic material. The dominance of hot runner injection molding in the microinjection molded plastic market can be attributed to its efficiency, cost-effectiveness, and ability to produce high-quality and consistent parts. These advantages align well with the requirements of industries relying on microplastic components, including automotive, electronics, medical devices, and consumer goods. By employing hot runner injection molding, manufacturers can achieve precise and intricate designs, reduce material waste, and enhance production efficiency, effectively meeting the demands of the market.

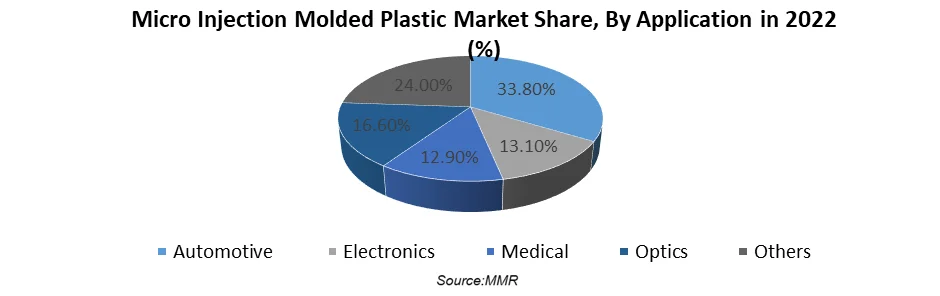

Based on the Application, the micro injection molded plastic market is dominated by the Electronics segment in the year 2022 and is expected to continue its dominance during the forecast period. In the electronics sector, micro injection molded plastic components are extensively utilized for a wide range of applications. These components play a crucial role in connectors, switches, housings, and other electronic parts that require precise dimensions, intricate designs, and high-performance characteristics. The growing trend of miniaturization in the electronics industry, driven by the demand for compact and lightweight devices, has further propelled the significance of micro injection molded plastic components. As technology advances, electronic devices are becoming increasingly compact and sophisticated. Micro injection molded plastic parts enable manufacturers to achieve the desired miniaturization while ensuring the functionality and reliability of the products. These components offer advantages such as enhanced electrical insulation, efficient thermal management, and resistance to environmental factors. The dominance of micro injection molded plastic components in the electronics industry stems from their ability to meet the stringent requirements of this sector.

Micro Injection Molded Plastic Market Regional Insights:

Asia Pacific region dominated the micro injection molded plastic market in the year 2022 and is expected to continue its dominance during the forecast period. The Asia Pacific region has experienced remarkable growth in industrialization, technological advancements, and manufacturing capabilities, establishing itself as a major hub for industries that rely on micro-injection molded plastic components. There are several significant aspects that contribute to Asia Pacific's dominance in this market. To begin with, the region has a strong consumer electronics industry, which is a major consumer of tiny injection molded plastic components. Leading electronics manufacturers and growing consumer electronics product demand in China, Japan, and South Korea have increased demand for these components. Furthermore, the Asia Pacific automotive sector has expanded tremendously as a result of factors such as rising disposable incomes, urbanization, and increased vehicle production. Micro injection molded plastic components find wide-ranging applications in automotive electronics, interior parts, and other critical components, playing a crucial role in the region's dominance. Asia Pacific also benefits from a well-established medical devices industry. Micro injection molded plastic components are integral to medical devices and equipment, including surgical instruments, drug delivery systems, and diagnostic devices. The region's robust manufacturing capabilities and its large consumer base contribute to its dominance in this sector. Moreover, Asia Pacific offers cost advantages in terms of production and labor compared to other regions. The presence of skilled labor, lower manufacturing costs, and supportive government initiatives for industrial development have attracted significant investments and manufacturing activities to the region. While Asia Pacific dominates the micro injection molded plastic market, other regions such as North America and Europe play vital roles as well. These regions have their distinct market dynamics and contribute significantly to the overall growth and development of the micro injection molded plastic industry.Global Micro Injection Molded Plastic Market Scope: Inquire before buying

Global Micro Injection Molded Plastic Market Report Coverage Details Base Year: 2022 Forecast Period: 2023-2029 Historical Data: 2018 to 2022 Market Size in 2022: US $ 1.1 Bn. Forecast Period 2023 to 2029 CAGR: 11.9% Market Size in 2029: US $ 2.2 Bn. Segments Covered: by Material Type Liquid Crystal Polymer (LCP) Polyether Ether Ketone (PEEK) Polycarbonate (PC) Polyethylene (PE) Polyoxymethylene (POM) Polymethyl Methacrylate (PMMA) Polyetherimide (PEI) Polybutylene Terephthalate (PBT) Others by Process Hot runner injection molding Cold runner injection molding Gas-assisted injection molding by Application Automotive Electronics Medical Optics Others Micro Injection Molded Plastic Market by Region

North America (United States, Canada, and Mexico) Europe (UK, France, Germany, Italy, Spain, Sweden, Austria, and the Rest of Europe) Asia Pacific (China, South Korea, Japan, India, Australia, Indonesia, Malaysia, Vietnam, Taiwan, Bangladesh, Pakistan, and Rest of APAC) Middle East and Africa (South Africa, GCC, Egypt, Nigeria, and the Rest of ME&A) South America (Brazil, Argentina Rest of South America)Micro Injection Molded Plastic Market Key Players

1. EVCO Plastics 2. Stack Plastics 3. Makuta Micro Injection Molding 4. American Precision Products 5. Accumold 6. HTI Plastics 7. Microdyne Plastics 8. Precimold 9. MTD Micro Molding 10.Rapidwerks 11.MedPlast 12.Sil-Pro 13.C&J Industries 14.PTA Plastics 15.Plastikos Inc. 16.Mold Craft Inc. 17.BMP Medical 18.Wittmann Battenfeld 19.Micromolding Solutions 20.Kamek Precision Tools Frequently Asked Questions: 1] What segments are covered in the Global Micro Injection Molded Plastic Market report? Ans. The segments covered in the Micro Injection Molded Plastic Market report are based on Material Type, Process, Application, and Regions. 2] Which region is expected to hold the highest share in the Global Micro Injection Molded Plastic Market? Ans. The Europe region is expected to hold the highest share of the Micro Injection Molded Plastic Market. 3] What is the market size of the Global Micro Injection Molded Plastic Market by 2029? Ans. The market size of the Market by 2029 is expected to reach US$ 2.2 Bn. 4] What is the forecast period for the Global Micro Injection Molded Plastic Market? Ans. The forecast period for the Micro Injection Molded Plastic Market is 2023-2029. 5] What was the market size of the Global Micro Injection Molded Plastic Market in 2022? Ans. The market size of the Market in 2022 was valued at US$ 1.1 Bn.

Table of Content: 1. Micro Injection Molded Plastic Market: Research Methodology 2. Micro Injection Molded Plastic Market: Executive Summary 3. Micro Injection Molded Plastic Market: Competitive Landscape 3.1. MMR Competition Matrix 3.2. Competitive Landscape 3.3. Key Players Benchmarking 3.4. Market Structure 3.4.1. Market Leaders 3.4.2. Market Followers 3.4.3. Emerging Players 3.5. Consolidation of the Market 4. Micro Injection Molded Plastic Market: Dynamics 4.1. Market Trends by region 4.1.1. North America 4.1.2. Europe 4.1.3. Asia Pacific 4.1.4. Middle East and Africa 4.1.5. South America 4.2. Market Drivers by Region 4.2.1. North America 4.2.2. Europe 4.2.3. Asia Pacific 4.2.4. Middle East and Africa 4.2.5. South America 4.3. Market Restraints 4.4. Market Opportunities 4.5. Market Challenges 4.6. PORTER’s Five Forces Analysis 4.7. PESTLE Analysis 4.8. Value Chain Analysis 4.9. Regulatory Landscape by Region 4.9.1. North America 4.9.2. Europe 4.9.3. Asia Pacific 4.9.4. Middle East and Africa 4.9.5. South America 5. Micro Injection Molded Plastic Market: Segmentation (by Value USD and Volume Units) 5.1. Micro Injection Molded Plastic Market, by Material Type (2022-2029) 5.1.1. Liquid Crystal Polymer (LCP) 5.1.2. Polyether Ether Ketone (PEEK) 5.1.3. Polycarbonate (PC) 5.1.4. Polyethylene (PE) 5.1.5. Polyoxymethylene (POM) 5.1.6. Polymethyl Methacrylate (PMMA) 5.1.7. Polyetherimide (PEI) 5.1.8. Polybutylene Terephthalate (PBT) 5.1.9. Others 5.2. Micro Injection Molded Plastic Market, by Process (2022-2029) 5.2.1. Hot runner injection molding 5.2.2. Cold runner injection molding 5.2.3. Gas-assisted injection molding 5.3. Micro Injection Molded Plastic Market, by Application (2022-2029) 5.3.1. Automotive 5.3.2. Electronics 5.3.3. Medical 5.3.4. Optics 5.3.5. Others 5.4. Micro Injection Molded Plastic Market, by Region (2022-2029) 5.4.1. North America 5.4.2. Europe 5.4.3. Asia Pacific 5.4.4. Middle East and Africa 5.4.5. South America 6. North America Micro Injection Molded Plastic Market (by Value USD and Volume Units) 6.1. North America Micro Injection Molded Plastic Market, by Material Type (2022-2029) 6.1.1. Liquid Crystal Polymer (LCP) 6.1.2. Polyether Ether Ketone (PEEK) 6.1.3. Polycarbonate (PC) 6.1.4. Polyethylene (PE) 6.1.5. Polyoxymethylene (POM) 6.1.6. Polymethyl Methacrylate (PMMA) 6.1.7. Polyetherimide (PEI) 6.1.8. Polybutylene Terephthalate (PBT) 6.1.9. Others 6.2. North America Micro Injection Molded Plastic Market, by Process (2022-2029) 6.2.1. Hot runner injection molding 6.2.2. Cold runner injection molding 6.2.3. Gas-assisted injection molding 6.3. North America Micro Injection Molded Plastic Market, by Application (2022-2029) 6.3.1. Automotive 6.3.2. Electronics 6.3.3. Medical 6.3.4. Optics 6.3.5. Others 6.4. North America Micro Injection Molded Plastic Market, by Country (2022-2029) 6.4.1. United States 6.4.2. Canada 6.4.3. Mexico 7. Europe Micro Injection Molded Plastic Market (by Value USD and Volume Units) 7.1. Europe Micro Injection Molded Plastic Market, by Material Type (2022-2029) 7.2. Europe Micro Injection Molded Plastic Market, by Process (2022-2029) 7.3. Europe Micro Injection Molded Plastic Market, by Application (2022-2029) 7.4. Europe Micro Injection Molded Plastic Market, by Country (2022-2029) 7.4.1. UK 7.4.2. France 7.4.3. Germany 7.4.4. Italy 7.4.5. Spain 7.4.6. Sweden 7.4.7. Austria 7.4.8. Rest of Europe 8. Asia Pacific Micro Injection Molded Plastic Market (by Value USD and Volume Units) 8.1. Asia Pacific Micro Injection Molded Plastic Market, by Material Type (2022-2029) 8.2. Asia Pacific Micro Injection Molded Plastic Market, by Process (2022-2029) 8.3. Asia Pacific Micro Injection Molded Plastic Market, by Application (2022-2029) 8.4. Asia Pacific Micro Injection Molded Plastic Market, by Country (2022-2029) 8.4.1. China 8.4.2. S Korea 8.4.3. Japan 8.4.4. India 8.4.5. Australia 8.4.6. Indonesia 8.4.7. Malaysia 8.4.8. Vietnam 8.4.9. Taiwan 8.4.10. Bangladesh 8.4.11. Pakistan 8.4.12. Rest of Asia Pacific 9. Middle East and Africa Micro Injection Molded Plastic Market (by Value USD and Volume Units) 9.1. Middle East and Africa Micro Injection Molded Plastic Market, by Material Type (2022-2029) 9.2. Middle East and Africa Micro Injection Molded Plastic Market, by Process (2022-2029) 9.3. Middle East and Africa Micro Injection Molded Plastic Market, by Application (2022-2029) 9.4. Middle East and Africa Micro Injection Molded Plastic Market, by Country (2022-2029) 9.4.1. South Africa 9.4.2. GCC 9.4.3. Egypt 9.4.4. Nigeria 9.4.5. Rest of ME&A 10. South America Micro Injection Molded Plastic Market (by Value USD and Volume Units) 10.1. South America Micro Injection Molded Plastic Market, by Material Type (2022-2029) 10.2. South America Micro Injection Molded Plastic Market, by Process (2022-2029) 10.3. South America Micro Injection Molded Plastic Market, by Application (2022-2029) 10.4. South America Micro Injection Molded Plastic Market, by Country (2022-2029) 10.4.1. Brazil 10.4.2. Argentina 10.4.3. Rest of South America 11. Company Profile: Key players 11.1. EVCO Plastics 11.1.1. Company Overview 11.1.2. Financial Overview 11.1.3. Business Portfolio 11.1.4. SWOT Analysis 11.1.5. Business Strategy 11.1.6. Recent Developments 11.2. Stack Plastics 11.3. Makuta Micro Injection Molding 11.4. American Precision Products 11.5. Accumold 11.6. HTI Plastics 11.7. Microdyne Plastics 11.8. Precimold 11.9. MTD Micro Molding 11.10. Rapidwerks 11.11. MedPlast 11.12. Sil-Pro 11.13. C&J Industries 11.14. PTA Plastics 11.15. Plastikos Inc. 11.16. Mold Craft Inc. 11.17. BMP Medical 11.18. Wittmann Battenfeld 11.19. Micromolding Solutions 11.20. Kamek Precision Tools 12. Key Findings 13. Process Recommendation