3D Printing Material Market Forecast 2019-2026. The medical miracle of recreating functioning body parts has come into reality now and the credit definitely goes to the insurgence of 3D printing in Manufacturing Landscape. Living cartilage cells can now be shaped into exact components needed to recreate noses, ears and other body parts. The journey of the Industrial world from Subtractive manufacturing towards Additive manufacturing has already begun. Additive Manufacturing popularly known as 3D Printing creates physical products from a digital design file by joining or forming input substrate materials using a layer-upon-layer printing approach.

Mass customization, lead time optimization, Supply chain simplification, waste reduction and ability to address complex geometries are some of the major driving forces for this technology to be optimistic about its promising future prospects. Its Trans-sectoral utility is a boon for multi-product manufacturers. Till now manufacturing industries were considering 3D printing for limited usage only e.g. For rapid prototyping, tooling, generating customised objects and complex geometries. Mass production incapability, standardization issues, High costs and low availability of 3-D printers were the few roadblocks in the way of accepting this technology with all its might. In spite of all these constraints, with the current advances, AM has been instrumental in bringing newer designs; cleaner, lighter, and safer products; shorter lead times and lower costs.

As compared to traditional manufacturing processes 3D Printing technology can produce components with fewer design restrictions. Furthermore lower handling cost as well as lower inventory cost, decentralized production, wider range of amenable materials, improved product quality, wastage reduction and reduced post processing are some other compelling driving forces to opt for this technology over traditional ones.

Maximize Market Research has carried out extensive research about the current Global 3D Printing Material Market outlook as well as the assuring future of the technology across various sectors. Research report comprehensively analyses the Manufacturing industry since its beginning and pinpoints the changing trends in manufacturing sector throughout the course of time. Further it gives a studied commentary over technological transformations in the industry over the period of the time. It highlights the inefficiency and low productivity of traditional manufacturing practices and advocates adaptation of newer technologies especially 3D printing as a promising alternative.

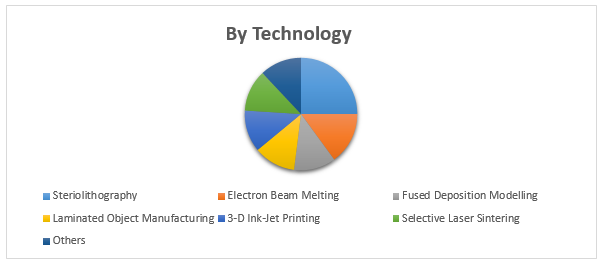

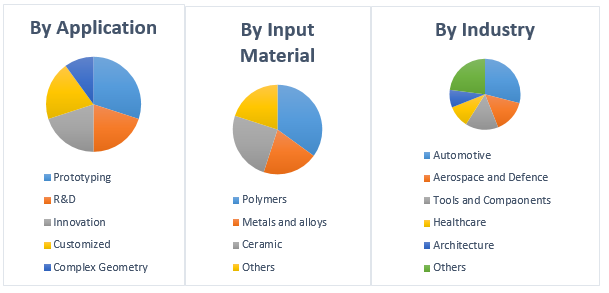

The driving forces as well as considerable restraints have been explained in depth. Further report segments the market by Technology, Industry, Input Material, Applications and Regions. Providing the comprehensive analysis of ecosystem of industry, which will be useful to take informed strategic decision to the stakeholders in the industry.

Importantly, the report delivers forecasts of the market, giving you an insight into the future opportunities that exist in the market. Global 3D printing Material market is expected to grow at CAGR of 15% during the forecast period of 2019-2026.

Major leading Manufacturers across various industries like Toyota, Ford, Mercedes-Benz from Automotive industry are adopting AM technology to produce essential machine parts. Organovo, Cyfuse Biomedical are working in healthcare sector and using 3D Bio printing to print tissues and organs and for research purposes too. This shows the signs of a favourable change in the Global 3D Printing Material Market. The manufacturing world is at the doorstep of next industrial revolution and it will not be a surprise that 3D Printing has to play a pivotal and decisive role in it.

Global 3D Printing Material Market – Industry Analysis and Forecast (2019-2026)