The Thin Wafer Processing and Dicing Equipment Market size was valued at USD 640.66 Billion in 2023 and the total Thin Wafer Processing and Dicing Equipment revenue is expected to grow at a CAGR of 6.5 % from 2024 to 2030, reaching nearly USD 995.58 Billion by 2030. Thin wafer processing equipment fabricates ultra-thin semiconductor wafers for flexible and high-performance applications, while dicing equipment precisely separates integrated circuits from wafers, ensuring accuracy in electronic component production. The increasing demand for miniaturized electronic devices across various industries such as consumer electronics, automotive, and healthcare driving the growth of The Thin Wafer Processing and Dicing Equipment Market. The market growth scenario reflects a rising emphasis on thin wafer processing equipment to fabricate semiconductor wafers with reduced thickness, enabling advancements in flexibility, performance, and miniaturization. While, dicing equipment plays a major role in semiconductor manufacturing, ensuring precise separation of integrated circuits from wafers to meet stringent quality and reliability standards. The Thin Wafer Processing and Dicing Equipment Market Key growth factors include technological advancements in equipment design, such as laser-based dicing systems and advanced thinning techniques, coupled with the expanding semiconductor industry's footprint in emerging economies. The growing adoption of 5G technology, artificial intelligence, and Internet of Things (IoT) devices is boosting demand for thin wafer processing and dicing equipment to support the production of high-performance chips. Recent developments by The Thin Wafer Processing and Dicing Equipment Market key players include strategic collaborations, product launches, and investments in research and development to enhance equipment efficiency, throughput, and precision. For instance, companies such as Disco Corporation, Tokyo Electron Limited, and Applied Materials Inc. have introduced innovative solutions focused on improving wafer thinning and dicing processes, addressing the evolving needs of semiconductor manufacturers worldwide. These advancements aim to fulfil to the increasing demand for advanced semiconductor devices while maintaining high levels of productivity and yield, driving the growth trajectory of the thin wafer processing and dicing equipment market in the forecast period.To know about the Research Methodology :- Request Free Sample Report Thin Wafer Processing and Dicing Equipment Market Dynamics: Increasing Demand for Miniaturized Electronic Devices Driving Thin Wafer Processing and Dicing Equipment Market Growth The demand for thin wafer processing and dicing equipment is driven by the increasing need for thinned wafers driven by consumer applications such as smartphones, smart cards, and stacked packages. The market for thinned wafers, used in various applications including MEMS devices, CMOS Image Sensors, memory, logic devices, and power devices, is estimated to have exceeded 16.5 million 8-inch wafer starts per year (WSPY) in 2025 and is expected to reach nearly 32 million 8-inch WSPY by 2030, representing a compound annual growth rate (CAGR) of 14%. Thinner wafers offer several benefits, including enabling thin packaging with improved form factors, enhanced electrical performance, and superior heat dissipation. The growth in the thin wafer processing and dicing equipment market is boosted by technological advancements such as the TAIKO process developed by DISCO for backside metallization layer in power devices. This innovative thinning process has already entered mass production, fulfiling to the evolving needs of manufacturers like Infineon and STMicroelectronics. The evolution of dicing technology is driven by the demand for thinner wafers and stronger die, with mechanical dicing being the most common method, supplemented by alternative technologies such as stealth dicing and plasma dicing based on deep reactive ion etching technology. The dicing equipment market, is expected to double by 2029-2030. Companies such as DISCO lead in blade dicing products, while Accretech dominates in stealth dicing. However, emerging players like Plasma-Therm, Orbotech/SPTS, and Panasonic are challenging the landscape with plasma dicing tools, offering promising alternatives for semiconductor manufacturers. This comprehensive overview of dicing technologies and equipment benchmarks their features, applications, and competitive landscape, providing valuable insights for stakeholders in the thin wafer processing and dicing equipment market. Complexity in MEMS and Advanced Packaging Hinders the Thin Wafer Processing and Dicing Equipment Market Growth Rising demand for higher memory densities and functionality, the industry faces mounting pressure to meet reliability, manufacturability, cost, and yield requirements have challenges such as particularly in packaging where wafer thinning and dicing processes encounter hurdles and hinders the growth of Thin Wafer Processing and Dicing Equipment Market. Challenges arise from thin film stresses within wafers during memory cell fabrication, leading to complications in wafer preparation and assembly. While mechanical dicing is conventional, it introduces issues like chipping and reduced die strength, necessitating alternative methods such as laser ablation and stealth dicing. Yet, adopting these alternatives adds complexity and cost, thereby impacting overall production efficiency and yield, highlighting a major hurdle in the Thin Wafer Processing and Dicing Equipment Market growth. Handling thin and fragile memory die during the die attach process poses additional challenges, demanding specialized tools and techniques to minimize stress and prevent die cracking. The necessity for automatic optical inspection to detect post-die attach cracks further complicates processes, adding layers of complexity and cost. The emergence of integrated devices such as solid-state drives (SSDs) and consumer system-in-package (SiP) modules introduces unique challenges for package design and assembly. These challenges include the demand for higher stacking and reduced space for wire bond fingers and passive components, driving the need for thin substrates capable of supporting increased routing. Consequently, the market grapples with heightened complexity in packaging design and assembly, underscoring the urgent need for innovative solutions to ensure high reliability, manufacturability, and yield while addressing evolving semiconductor application demands.

Thin Wafer Processing and Dicing Equipment Market Segment Analysis:

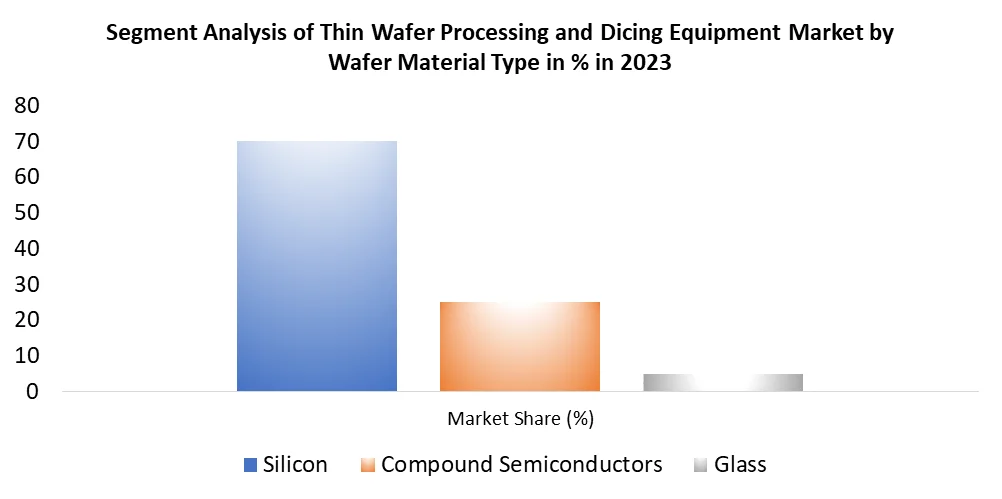

Based on Type of Wafer Material, Silicon wafers dominated the market in Thin Wafer Processing and Dicing Equipment Market in 2023 due to their extensive use in traditional semiconductor devices such as integrated circuits (ICs), MEMS devices, and CMOS image sensors. The widespread adoption of silicon wafers is driven by their superior electrical properties, reliability, and cost-effectiveness. In contrast, compound semiconductor wafers, including materials like gallium arsenide (GaAs) and silicon carbide (SiC), find niche applications in high-frequency and power electronics, optoelectronics, and RF devices due to their superior performance in specific applications requiring high-speed operation and high-temperature resistance. Glass wafers, while less common, are gaining traction in emerging applications such as microfluidics, bioMEMS, and optical devices due to their excellent optical transparency, chemical inertness, and biocompatibility, offering unique advantages in specialized areas such as biomedical and optical industries.

Thin Wafer Processing and Dicing Equipment Market Regional Insights:

Asia Pacific Dominates the Thin Wafer Processing and Dicing Equipment Market Asia Pacific dominated the Thin Wafer Processing and Dicing Equipment Market in 2023 as it is most rapidly growing semiconductor market globally, driven by robust demand for smartphones and consumer electronics devices, particularly in countries like China, South Korea, and Singapore. The region's prominence is evident in strategic business moves, such as Wingtech's acquisition of Newport Wafer Fab in August 2021, underscoring China's focus on expanding through mergers and acquisitions. Japan, with its strong semiconductor and electronics industry, plays a pivotal role, although it faces challenges such as high production costs and exchange rate fluctuations. In contrast, Australia experiences market growth propelled by a flourishing electronics manufacturing sector and increased adoption of advanced devices, particularly in televisions and smartphones. In a bid to bolster semiconductor supply chain security, the Quad Alliance, comprising Australia, India, the United States, and Japan, initiated a semiconductor supply chain initiative in October 2021. India, currently reliant on semiconductor imports, unveiled a comprehensive program in December 2021 to develop its semiconductor and display manufacturing ecosystem, aiming for economic independence and technological leadership. The Asia Pacific region significantly influences the growth trajectory of fully autonomous automobiles, driven by technological advancements, consumer acceptance, pricing, and OEMs' capacity to address safety concerns. This dynamic landscape underscores continuous efforts by the automotive and semiconductor industries to enhance technologies and ensure reliable integration of autonomous features into vehicles.Thin Wafer Processing and Dicing Equipment Market Scope: Inquire before buying

Global Thin Wafer Processing and Dicing Equipment Market Report Coverage Details Base Year: 2023 Forecast Period: 2024-2030 Historical Data: 2018 to 2023 Market Size in 2023: US $ 640.66 Bn. Forecast Period 2024 to 2030 CAGR: 6.5% Market Size in 2030: US $ 995.58 Bn. Segments Covered: by Type of Wafer Material Silicon Compound Semiconductors Glass by Technology Type Dicing Equipment Thin Wafer Processing Equipment by Wafer Size 300mm Wafer 200mm Wafer Other Sizes by Application MEMS (Micro-Electro-Mechanical Systems) CMOS Image Sensors RF Devices Memory Devices Logic and Power Devices by End-User Semiconductor Manufacturing Electronics Automotive Healthcare Aerospace Industries) Thin Wafer Processing and Dicing Equipment Market, By Region

North America (United States, Canada and Mexico) Europe (UK, France, Germany, Italy, Spain, Sweden, Austria and Rest of Europe) Asia Pacific (China, South Korea, Japan, India, Australia, Indonesia, Malaysia, Vietnam, Taiwan, Bangladesh, Pakistan and Rest of APAC) Middle East and Africa (South Africa, GCC, Egypt, Nigeria and Rest of ME&A) South America (Brazil, Argentina Rest of South America)Thin Wafer Processing and Dicing Equipment Market Key Players

North America: 1. Dynatex International, Petaluma, California, United States 2. Modutek Corporation, San Jose, California, United States 3. Technotronix Corporation, San Jose, California, United States 4. Axus Technology, Chandler, Arizona, United States 5. Plasma-Therm LLC, Saint Petersburg, Florida, United States Europe: 1. Advanced Dicing Technologies Ltd., Yokneam, Israel 2. Loadpoint Ltd., Rye, United Kingdom 3. SUSS MicroTec SE, Garching, Germany 4. Microdiamant AG, Lengwil, Switzerland 5. Meyer Burger Technology AG, Thun, Switzerland Asia-Pacific: 1. Disco Corporation, Tokyo, Japan 2. Accretech, Tokyo, Japan 3. Hanmi Semiconductor Co., Ltd., Chungcheongbuk-do, South Korea 4. Nagase Integrex Co., Ltd., Tokyo, Japan 5. Tokyo Seimitsu Co., Ltd., Tokyo, Japan FAQs: 1] What Major Key players in the Global Thin Wafer Processing and Dicing Equipment Market report? Ans. The Major Key players covered in the Market report are Disco Corporation,Accretech,Hanmi Semiconductor Co., Ltd., Nagase Integrex Co., Ltd.,Tokyo Seimitsu Co., Ltd. Navenio,Huq Industries Limited,Cambium Networks Ltd,Purple,OpenSignal,Relayr,Briteyellow,WiCastr 2] Which region is expected to hold the highest share in the Global Thin Wafer Processing and Dicing Equipment Market? Ans. Asia Pacific region is expected to hold the highest share in the Market. 3] What is the market size of the Global Market by 2030? Ans. The market size of the Market by 2030 is expected to reach US$ 995.58 Billion. 4] What is the forecast period for the Global Market? Ans. The forecast period for the Market is 2024-2030. 5] What was the market size of the Global Market in 2023? Ans. The market size of the Market in 2023 was valued at US$ 640.66 Billion.

1. Thin Wafer Processing and Dicing Equipment Market: Research Methodology 2. Thin Wafer Processing and Dicing Equipment Market Introduction 2.1. Study Assumption and Market Definition 2.2. Scope of the Study 2.3. Executive Summary 3. Thin Wafer Processing and Dicing Equipment Market: Dynamics 3.1. Thin Wafer Processing and Dicing Equipment Market Trends by Region 3.1.1. North America Thin Wafer Processing and Dicing Equipment Market Trends 3.1.2. Europe Thin Wafer Processing and Dicing Equipment Market Trends 3.1.3. Asia Pacific Thin Wafer Processing and Dicing Equipment Market Trends 3.1.4. Middle East and Africa Thin Wafer Processing and Dicing Equipment Market Trends 3.1.5. South America Thin Wafer Processing and Dicing Equipment Market Trends 3.2. Thin Wafer Processing and Dicing Equipment Market Dynamics by Region 3.2.1. North America 3.2.1.1. North America Thin Wafer Processing and Dicing Equipment Market Drivers 3.2.1.2. North America Thin Wafer Processing and Dicing Equipment Market Restraints 3.2.1.3. North America Thin Wafer Processing and Dicing Equipment Market Opportunities 3.2.1.4. North America Thin Wafer Processing and Dicing Equipment Market Challenges 3.2.2. Europe 3.2.2.1. Europe Thin Wafer Processing and Dicing Equipment Market Drivers 3.2.2.2. Europe Thin Wafer Processing and Dicing Equipment Market Restraints 3.2.2.3. Europe Thin Wafer Processing and Dicing Equipment Market Opportunities 3.2.2.4. Europe Thin Wafer Processing and Dicing Equipment Market Challenges 3.2.3. Asia Pacific 3.2.3.1. Asia Pacific Thin Wafer Processing and Dicing Equipment Market Drivers 3.2.3.2. Asia Pacific Thin Wafer Processing and Dicing Equipment Market Restraints 3.2.3.3. Asia Pacific Thin Wafer Processing and Dicing Equipment Market Opportunities 3.2.3.4. Asia Pacific Thin Wafer Processing and Dicing Equipment Market Challenges 3.2.4. Middle East and Africa 3.2.4.1. Middle East and Africa Thin Wafer Processing and Dicing Equipment Market Drivers 3.2.4.2. Middle East and Africa Thin Wafer Processing and Dicing Equipment Market Restraints 3.2.4.3. Middle East and Africa Thin Wafer Processing and Dicing Equipment Market Opportunities 3.2.4.4. Middle East and Africa Thin Wafer Processing and Dicing Equipment Market Challenges 3.2.5. South America 3.2.5.1. South America Thin Wafer Processing and Dicing Equipment Market Drivers 3.2.5.2. South America Thin Wafer Processing and Dicing Equipment Market Restraints 3.2.5.3. South America Thin Wafer Processing and Dicing Equipment Market Opportunities 3.2.5.4. South America Thin Wafer Processing and Dicing Equipment Market Challenges 3.3. PORTER’s Five Forces Analysis 3.4. PESTLE Analysis 3.5. Technology Roadmap 3.6. Regulatory Landscape by Region 3.6.1. North America 3.6.2. Europe 3.6.3. Asia Pacific 3.6.4. Middle East and Africa 3.6.5. South America 3.7. Key Opinion Leader Analysis For Thin Wafer Processing and Dicing Equipment Industry 3.8. Analysis of Government Schemes and Initiatives For Thin Wafer Processing and Dicing Equipment Industry 3.9. The Global Pandemic Impact on Thin Wafer Processing and Dicing Equipment Market 4. Thin Wafer Processing and Dicing Equipment Market: Global Market Size and Forecast by Segmentation (by Value in USD Million) (2023-2030) 4.1. Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 4.1.1. Silicon 4.1.2. Compound Semiconductors 4.1.3. Glass 4.2. Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 4.2.1. Dicing Equipment 4.2.2. Thin Wafer Processing Equipment 4.3. Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 4.3.1. 300mm Wafer 4.3.2. 200mm Wafer 4.3.3. Other Sizes 4.4. Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 4.4.1. MEMS (Micro-Electro-Mechanical Systems) 4.4.2. CMOS Image Sensors 4.4.3. RF Devices 4.4.4. Memory Devices 4.4.5. Logic and Power Devices 4.5. Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 4.5.1. Semiconductor Manufacturing 4.5.2. Electronics 4.5.3. Automotive 4.5.4. Healthcare 4.5.5. Aerospace Industries 4.6. Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Region (2023-2030) 4.6.1. North America 4.6.2. Europe 4.6.3. Asia Pacific 4.6.4. Middle East and Africa 4.6.5. South America 5. North America Thin Wafer Processing and Dicing Equipment Market Size and Forecast by Segmentation (by Value in USD Million) (2023-2030) 5.1. North America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 5.1.1. Silicon 5.1.2. Compound Semiconductors 5.1.3. Glass 5.2. North America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 5.2.1. Dicing Equipment 5.2.2. Thin Wafer Processing Equipment 5.3. North America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 5.3.1. 300mm Wafer 5.3.2. 200mm Wafer 5.3.3. Other Sizes 5.4. North America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 5.4.1. MEMS (Micro-Electro-Mechanical Systems) 5.4.2. CMOS Image Sensors 5.4.3. RF Devices 5.4.4. Memory Devices 5.4.5. Logic and Power Devices 5.5. North America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 5.5.1. Semiconductor Manufacturing 5.5.2. Electronics 5.5.3. Automotive 5.5.4. Healthcare 5.5.5. Aerospace Industries 5.6. Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Country (2023-2030) 5.6.1. United States 5.6.1.1. United States Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 5.6.1.1.1. Silicon 5.6.1.1.2. Compound Semiconductors 5.6.1.1.3. Glass 5.6.1.2. United States Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 5.6.1.2.1. Dicing Equipment 5.6.1.2.2. Thin Wafer Processing Equipment 5.6.1.3. United States Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 5.6.1.3.1. 300mm Wafer 5.6.1.3.2. 200mm Wafer 5.6.1.3.3. Other Sizes 5.6.1.4. United States Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 5.6.1.4.1. MEMS (Micro-Electro-Mechanical Systems) 5.6.1.4.2. CMOS Image Sensors 5.6.1.4.3. RF Devices 5.6.1.4.4. Memory Devices 5.6.1.4.5. Logic and Power Devices 5.6.1.5. United States Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 5.6.1.5.1. Semiconductor Manufacturing 5.6.1.5.2. Electronics 5.6.1.5.3. Automotive 5.6.1.5.4. Healthcare 5.6.1.5.5. Aerospace Industries 5.6.2. Canada 5.6.2.1. Canada Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 5.6.2.1.1. Silicon 5.6.2.1.2. Compound Semiconductors 5.6.2.1.3. Glass 5.6.2.2. Canada Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 5.6.2.2.1. Dicing Equipment 5.6.2.2.2. Thin Wafer Processing Equipment 5.6.2.3. Canada Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 5.6.2.3.1. 300mm Wafer 5.6.2.3.2. 200mm Wafer 5.6.2.3.3. Other Sizes 5.6.2.4. Canada Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 5.6.2.4.1. MEMS (Micro-Electro-Mechanical Systems) 5.6.2.4.2. CMOS Image Sensors 5.6.2.4.3. RF Devices 5.6.2.4.4. Memory Devices 5.6.2.4.5. Logic and Power Devices 5.6.2.5. Canada Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 5.6.2.5.1. Semiconductor Manufacturing 5.6.2.5.2. Electronics 5.6.2.5.3. Automotive 5.6.2.5.4. Healthcare 5.6.2.5.5. Aerospace Industries 5.6.3. Mexico 5.6.3.1. Mexico Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 5.6.3.1.1. Silicon 5.6.3.1.2. Compound Semiconductors 5.6.3.1.3. Glass 5.6.3.2. Mexico Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 5.6.3.2.1. Dicing Equipment 5.6.3.2.2. Thin Wafer Processing Equipment 5.6.3.3. Mexico Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 5.6.3.3.1. 300mm Wafer 5.6.3.3.2. 200mm Wafer 5.6.3.3.3. Other Sizes 5.6.3.4. Mexico Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 5.6.3.4.1. MEMS (Micro-Electro-Mechanical Systems) 5.6.3.4.2. CMOS Image Sensors 5.6.3.4.3. RF Devices 5.6.3.4.4. Memory Devices 5.6.3.4.5. Logic and Power Devices 5.6.3.5. Mexico Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 5.6.3.5.1. Semiconductor Manufacturing 5.6.3.5.2. Electronics 5.6.3.5.3. Automotive 5.6.3.5.4. Healthcare 5.6.3.5.5. Aerospace Industries 6. Europe Thin Wafer Processing and Dicing Equipment Market Size and Forecast by Segmentation (by Value in USD Million) (2023-2030) 6.1. Europe Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 6.2. Europe Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 6.3. Europe Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 6.4. Europe Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 6.5. Europe Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 6.6. Europe Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Country (2023-2030) 6.6.1. United Kingdom 6.6.1.1. United Kingdom Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 6.6.1.2. United Kingdom Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 6.6.1.3. United Kingdom Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 6.6.1.4. United Kingdom Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 6.6.1.5. United Kingdom Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 6.6.2. France 6.6.2.1. France Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 6.6.2.2. France Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 6.6.2.3. France Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 6.6.2.4. France Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 6.6.2.5. France Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 6.6.3. Germany 6.6.3.1. Germany Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 6.6.3.2. Germany Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 6.6.3.3. Germany Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 6.6.3.4. Germany Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 6.6.3.5. Germany Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 6.6.4. Italy 6.6.4.1. Italy Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 6.6.4.2. Italy Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 6.6.4.3. Italy Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 6.6.4.4. Italy Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 6.6.4.5. Italy Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 6.6.5. Spain 6.6.5.1. Spain Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 6.6.5.2. Spain Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 6.6.5.3. Spain Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 6.6.5.4. Spain Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 6.6.5.5. Spain Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 6.6.6. Sweden 6.6.6.1. Sweden Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 6.6.6.2. Sweden Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 6.6.6.3. Sweden Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 6.6.6.4. Sweden Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 6.6.6.5. Sweden Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 6.6.7. Austria 6.6.7.1. Austria Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 6.6.7.2. Austria Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 6.6.7.3. Austria Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 6.6.7.4. Austria Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 6.6.7.5. Austria Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 6.6.8. Rest of Europe 6.6.8.1. Rest of Europe Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 6.6.8.2. Rest of Europe Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 6.6.8.3. Rest of Europe Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 6.6.8.4. Rest of Europe Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 6.6.8.5. Rest of Europe Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 7. Asia Pacific Thin Wafer Processing and Dicing Equipment Market Size and Forecast by Segmentation (by Value in USD Million) (2023-2030) 7.1. Asia Pacific Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 7.2. Asia Pacific Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 7.3. Asia Pacific Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 7.4. Asia Pacific Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 7.5. Asia Pacific Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 7.6. Asia Pacific Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Country (2023-2030) 7.6.1. China 7.6.1.1. China Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 7.6.1.2. China Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 7.6.1.3. China Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 7.6.1.4. China Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 7.6.1.5. China Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 7.6.2. S Korea 7.6.2.1. S Korea Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 7.6.2.2. S Korea Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 7.6.2.3. S Korea Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 7.6.2.4. S Korea Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 7.6.2.5. S Korea Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 7.6.3. Japan 7.6.3.1. Japan Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 7.6.3.2. Japan Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 7.6.3.3. Japan Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 7.6.3.4. Japan Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 7.6.3.5. Japan Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 7.6.4. India 7.6.4.1. India Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 7.6.4.2. India Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 7.6.4.3. India Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 7.6.4.4. India Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 7.6.4.5. India Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 7.6.5. Australia 7.6.5.1. Australia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 7.6.5.2. Australia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 7.6.5.3. Australia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 7.6.5.4. Australia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 7.6.5.5. Australia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 7.6.6. Indonesia 7.6.6.1. Indonesia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 7.6.6.2. Indonesia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 7.6.6.3. Indonesia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 7.6.6.4. Indonesia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 7.6.6.5. Indonesia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 7.6.7. Malaysia 7.6.7.1. Malaysia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 7.6.7.2. Malaysia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 7.6.7.3. Malaysia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 7.6.7.4. Malaysia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 7.6.7.5. Malaysia Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 7.6.8. Vietnam 7.6.8.1. Vietnam Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 7.6.8.2. Vietnam Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 7.6.8.3. Vietnam Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 7.6.8.4. Vietnam Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 7.6.8.5. Vietnam Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 7.6.9. Taiwan 7.6.9.1. Taiwan Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 7.6.9.2. Taiwan Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 7.6.9.3. Taiwan Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 7.6.9.4. Taiwan Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 7.6.9.5. Taiwan Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 7.6.10. Rest of Asia Pacific 7.6.10.1. Rest of Asia Pacific Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 7.6.10.2. Rest of Asia Pacific Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 7.6.10.3. Rest of Asia Pacific Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 7.6.10.4. Rest of Asia Pacific Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 7.6.10.5. Rest of Asia Pacific Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 8. Middle East and Africa Thin Wafer Processing and Dicing Equipment Market Size and Forecast by Segmentation (by Value in USD Million) (2023-2030 8.1. Middle East and Africa Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 8.2. Middle East and Africa Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 8.3. Middle East and Africa Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 8.4. Middle East and Africa Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 8.5. Middle East and Africa Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 8.6. Middle East and Africa Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Country (2023-2030) 8.6.1. South Africa 8.6.1.1. South Africa Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 8.6.1.2. South Africa Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 8.6.1.3. South Africa Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 8.6.1.4. South Africa Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 8.6.1.5. South Africa Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 8.6.2. GCC 8.6.2.1. GCC Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 8.6.2.2. GCC Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 8.6.2.3. GCC Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 8.6.2.4. GCC Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 8.6.2.5. GCC Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 8.6.3. Nigeria 8.6.3.1. Nigeria Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 8.6.3.2. Nigeria Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 8.6.3.3. Nigeria Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 8.6.3.4. Nigeria Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 8.6.3.5. Nigeria Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 8.6.4. Rest of ME&A 8.6.4.1. Rest of ME&A Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 8.6.4.2. Rest of ME&A Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 8.6.4.3. Rest of ME&A Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 8.6.4.4. Rest of ME&A Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 8.6.4.5. Rest of ME&A Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 9. South America Thin Wafer Processing and Dicing Equipment Market Size and Forecast by Segmentation (by Value in USD Million) (2023-2030) 9.1. South America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 9.2. South America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 9.3. South America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 9.4. South America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 9.5. South America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 9.6. South America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Country (2023-2030) 9.6.1. Brazil 9.6.1.1. Brazil Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 9.6.1.2. Brazil Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 9.6.1.3. Brazil Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 9.6.1.4. Brazil Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 9.6.1.5. Brazil Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 9.6.2. Argentina 9.6.2.1. Argentina Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 9.6.2.2. Argentina Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 9.6.2.3. Argentina Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 9.6.2.4. Argentina Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 9.6.2.5. Argentina Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 9.6.3. Rest Of South America 9.6.3.1. Rest Of South America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Type of Wafer Material (2023-2030) 9.6.3.2. Rest Of South America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Technology Type (2023-2030) 9.6.3.3. Rest Of South America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Wafer Size (2023-2030) 9.6.3.4. Rest Of South America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by Application (2023-2030) 9.6.3.5. Rest Of South America Thin Wafer Processing and Dicing Equipment Market Size and Forecast, by End-User (2023-2030) 10. Global Thin Wafer Processing and Dicing Equipment Market: Competitive Landscape 10.1. MMR Competition Matrix 10.2. Competitive Landscape 10.3. Key Players Benchmarking 10.3.1. Company Name 10.3.2. Service Segment 10.3.3. End-user Segment 10.3.4. Revenue (2023) 10.3.5. Company Locations 10.4. Leading Thin Wafer Processing and Dicing Equipment Market Companies, by Market Capitalization 10.5. Market Structure 10.5.1. Market Leaders 10.5.2. Market Followers 10.5.3. Emerging Players 10.6. Mergers and Acquisitions Details 11. Company Profile: Key Players 11.1. Disco Corporation, Tokyo, Japan 11.1.1. Company Overview 11.1.2. Business Portfolio 11.1.3. Financial Overview 11.1.4. SWOT Analysis 11.1.5. Strategic Analysis 11.1.6. Scale of Operation (Small, Medium, and Large) 11.1.7. Details on Partnership 11.1.8. Regulatory Accreditations and Certifications Received by Them 11.1.9. Awards Received by the Firm 11.1.10. Recent Developments 11.2. Accretech, Tokyo, Japan 11.3. Hanmi Semiconductor Co., Ltd., Chungcheongbuk-do, South Korea 11.4. Nagase Integrex Co., Ltd., Tokyo, Japan 11.5. Tokyo Seimitsu Co., Ltd., Tokyo, Japan 11.6. Advanced Dicing Technologies Ltd., Yokneam, Israel 11.7. Loadpoint Ltd., Rye, United Kingdom 11.8. SUSS MicroTec SE, Garching, Germany 11.9. Microdiamant AG, Lengwil, Switzerland 11.10. Meyer Burger Technology AG, Thun, Switzerland 11.11. Dynatex International, Petaluma, California, United States 11.12. Modutek Corporation, San Jose, California, United States 11.13. Technotronix Corporation, San Jose, California, United States 11.14. Axus Technology, Chandler, Arizona, United States 11.15. Plasma-Therm LLC, Saint Petersburg, Florida, United States 12. Key Findings 13. Industry Recommendations